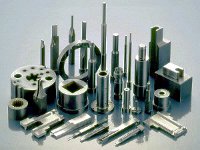

Product Information

Products made with Mizuho-loy's cemented carbide tools and metal moulds have been used in a wide variety of fields, including but not limited to electronics, electrical machinery, industrial equipment, construction equipment, automobiles, ships, tableware, and household goods. From now into the future, we will continue to listen to our customers and strive for further excellence during our creation of new products.

| Telecommunications | Telecommunications Press dies for electromagnetic powders, IC lead frame dies, carbide dies for semiconductors, etc. |

| Automotive | Cold-forged automotive equipment, various hot-press moulds, moulds for powder dies, etc. |

| Industrial Equipment | Varied press dies, edged tools, specialized bits, varied blades, varied punches, continuous blanking moulds, etc. |

| Ironworking | Carbide rolls, cold-forming dies, header dies, irregular dies, etc. |

| Mining/Construction | Triamant, auger/drilling bits, boring bits, drill bits, nozzles, etc. |

Products aside from our cemented carbides

We also handle a wide range of products aside from cemented carbides, such as steel (alloy tool steel, high-speed steel, stainless steel) aluminum, etc. Please don't hesitate to consult us regarding non-carbide products.

Precision Press Dies

Specialized Precision Punches

Battery-related Dies

Powder Pressing Dies

Cold Press Dies

Automatic Machine Parts

Cemented Carbide Materials

Specialized Chips

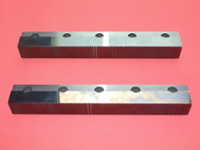

Carbide Blades

Circular Blades

Die Parts

Materials Lis

Before using Mizuho-loy's carbide tools, in order to optimize their effectiveness, we ask that our customers select a material best suited to their product's intended use and use environment.

We have provided the following materials to adapt to various types of work environments.

For more details regarding the suitability of the listed materials, please contact us. Depending on the situation, we may suggest a material that is not listed on our catalogue.

Materials Chart

| Classification | CIS Classification | Our Grade | Hardness(HRA) | Density(g/cm3) | Transverse Rupture Strength(MPa) | Primary Uses |

| Ultra-fine Powder | VF10 | K2 | 94.0 | 14.65 | 3200 | Superhard material for precision tools |

| VF20 | VX35 | 92.8 | 14.40 | 3400 | Micro-diameter tools, stamping plates, dies for electronic parts | |

| VF30 | VX06 | 91.4 | 13.90 | 3800 | Pots, plunger heads for IC packing | |

| VF40 | VX07 | 89.9 | 13.50 | 3300 | Single pots | |

| VF30 (Z20) |

G6F | 91.2 | 14.20 | 3200 | Precision dies, punches, blades, stainless punches, endmills, tie bar cut dies | |

| Ultra-fine Powder: High-temperature, wear-resistant | VF20 (K01) |

MX02 | 92.8 | 14.91 | 2400 | Endmills for machining carbon, wood cutting blades, nozzles |

| Ultra-fine Powder, corrosion-resistant | VF10 | RT1A | 93.3 | 14.95 | 1800 | Nozzle |

| VF30 | G3A | 91.2 | 14.40 | 3000 | Precision dies, punches, cut dies | |

| VF40 | G5A | 90.4 | 14.25 | 3500 | Precision dies, punches, cut blades | |

| VF50 | G7A | 88.7 | 13.60 | 3500 | Cutters | |

| For Hot Processing | RC50 | G6N | 87.8 | 14.30 | 2800 | Hot dies, hot punches |

| RU70 | G7N | 83.5 | 13.50 | 2600 | Hot dies, hot punches | |

| General Alloys | VM20 (K10) |

G1 | 92.0 | 15.00 | 2700 | Wire dies, plugs, blades, nozzles, guides |

| VM30 (K20) |

G2 | 91.0 | 14.80 | 3000 | Reducing dies, guides, wire dies, roll centers, blades, dies, punches, chucks | |

| VM40 (K30) |

G3 | 90.0 | 14.50 | 3200 | Reducing dies, largedies, rolls, dies, punches, endmills | |

| VM40 | G5 | 89.0 | 14.30 | 3400 | Reducing dies, large dies, rolls, guide strippers, dies, punches | |

| VM50 | G5C | 88.5 | 14.30 | 3000 | Precision dies | |

| Coarse Powder, shock-resistant | VC50 (E4) |

G6 | 87.5 | 14.00 | 3000 | Reducing dies,drawing dies, punching dies, header dies, header punches, tips, bits, scrapers |

| VU60 (E5) |

SG5 | 86.5 | 14.30 | 2600 | Boring tips, earth auger bits, bits | |

| VU70 | G7 | 83.5 | 13.60 | 2500 | Header dies, header punches, slitters, reduction dies | |

| Non-magnetic, corrosion-resistant | NM50 | NJ | 87.0 | 13.75 | 3000 | Non-magnetic powder dies, punches, bearings |

Material Characteristic Data Table 1 (WC particle diameter, Co - wt %, etc.)

| Our Grade | WC Particle Diameter(µm) |

Co(wt%) | Hardness (HRA) | Transverse Rupture Strength (MPa) | Principle Uses/Characteristics |

| G3A | 1.0 and less | 10.0 | 91.2 | 3000 |

|

| G5A | 1.0 and less | 12.0 | 90.4 | 3500 |

|

| G6F | 0.7 and less | 12.0 | 91.2 | 3200 |

|

| MX02 | 1.0 and less | 6.0 | 92.8 | 2400 |

|

| NJ | 1 - 2.0 | 16.0 ( Ni ) | 87 | 3000 |

|

| VX25 | 0.5 | 8.0 | 93.4 | 3600 |

|

| VX35 | 0.5 | 10.5 | 92.7 | 3700 |

|

Material Characteristic Data Table 2 (Coercivity, saturation magnetic flux density, crack resistance, Young's Modulus, etc.)

| Our Grade | Density (g/c㎥) |

Hardness (HRA) |

Coercivity (Oe) |

Saturation magnetic flux density (µT㎥/Kg) |

Crack Resistance (Kgf/mm) |

Transverse Rupture Strength (Mpa) |

Young's Modulus (GPa) |

| VX07 | 13.5 | 89.9 | 269 | 33.0 | 154 | 3300 | 561 |

| VX06 | 13.9 | 91.4 | 322 | 22.0 | 89 | 3800 | 571 |

| VX25 | 14.55 | 93.4 | 334 | 16.6 | 67 | 3600 | 613 |

| VX35 | 14.3 | 92.7 | 302 | 20.3 | 76 | 3700 | 610 |

| G6F | 14.2 | 91.2 | 269 | 24.0 | 93 | 3200 | 584 |

| G5 | 14.30 | 89.0 | 142 | 20.9 | 209 | 3400 | 581 |

| G5A | 14.25 | 90.4 | 196 | 19.5 | 123 | 3400 | 581 |

| G6 | 14 | 87.5 | 108 | 27.1 | 714 | 3000 | 510 |

Stages of Cemented Carbide Production (Mizuho Kyushu Co., Ltd.)

This is an overview of our company's cemented carbide production process. Sintering of carbides is done at our subsidiary, Mizuho Kyushu's Oita Factory, and all images are taken on-site.

1.Gathering Raw Materials/Powder

Raw materials purchased

- WC (Tungsten carbide powder)

- Co (Cobalt powder)

- Other additives

2.Combining and Mixing

The base powder is created by mixing and crushing raw material in ball mills and attritors, then drying the material in vacuum mixers.

3.Pressing (Cold Isostatic Pressing))

The combined base powders are pressurized and compacted in dry or wet CIPs

6. Sintering (Hot Isostatic Pressing)

The material is vacuum-sintered at a temperature of 1300 to 1500 degrees.

8.Processing

Equipment List

| Surface Grinder | 15台 | NC Profile Grinder | 15台 |

| All-Purpose Grinder | 5台 | NC Jig Grinder | 2台 |

| NC E.D.M. | 5台 | Precision Cylindrical Grinder | 10台 |

| Wire Cut | 10台 | NC Milling Machine | 3台 |

(Including partner factories)

9.Product Testing

10.Shipping

We pack the product carefully before sending it to our customers.